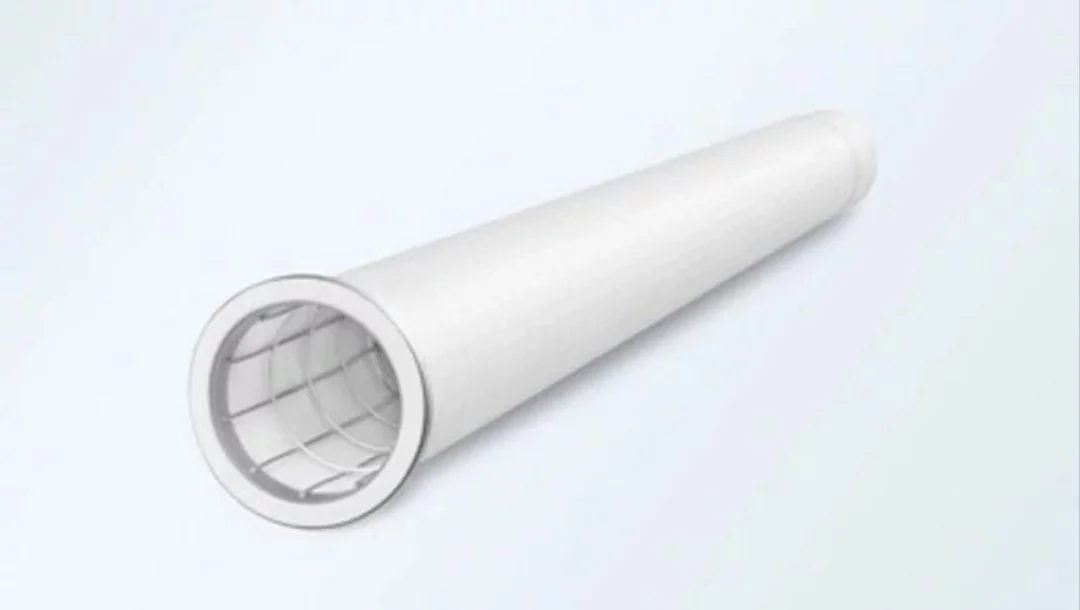

Pulse-Jet Filter Bags

Custom-sewn or welded bags built for high-energy reverse-pulse collectors in cement, steel, power and biomass plants. Ultra-microfibre construction lowers initial pressure drop and extends bag life.

Materials & Performance Windows

Media Family Max T (°C) Typical Applications Notes

Polyester 150 Grain, woodworking, general dust Cost-effective, good mechanical strength

EcoFlow Polyester 150 Power, cement Low basis weight for energy savings

PPS (ChemGuard) 190 Coal, biomass, chemical dryers Excellent acid/alkali resistance

Meta-Aramid (ThermaShield) 205 Asphalt, steel sinter, carbon black High temp + mechanical flex

P84® Blends 240 Incineration, kiln bypass Superior acid tolerance at high heat

PTFE / PTFE-blended 260 Non-ferrous smelting, carbon bake Peak chemical & thermal resistance

Custom-engineered for sub-5 mg/Nm³ emissions, longer life and lower energy use

Feature Benefit to Your Baghouse

UltraClean depth-gradient felt Captures sub-micron dust at the fibre surface without ePTFE membranes, keeping ΔP low from start-up onward.

Precision fibre blends Tailored combinations of PPS, aramid, P84® or PTFE handle acid peaks, high SO₂, or 260 °C kiln gas without embrittlement.

Low ΔP construction Up to 12 % fan-power saving versus standard 500 gsm polyester bags.

Abrasion-shield scrims & edge guards Withstand high-velocity inlets and mis-aligned cages; field data show 30–50 % longer change-out intervals.

Advanced surface finishes Options include singed, glazed, PTFE dip, oil & water repellent, anti-static or flame retardant each applied in-house for total control.

Full-service support FD pulse-mapping, on-site leak testing and crewed installations ensure design performance from day one—and through the millionth pulse.

-

Emission performance: proven ≤ 5 mg/Nm³ — routinely 2-3× cleaner than industry norms

Media portfolio: polyester, homopolymer & copolymer PPS, meta-aramid, P84®, PTFE blends, and our own UltraClean micro-fibre felts (< 1 µm)

Temperature window: continuous service up to 260 °C (ThermaShield range)

Chemical resistance: customised finishes for acid, alkali, hydrocarbon and moisture-laden gases

Dimensions: Ø 100 – 250 mm, lengths to 12 m (other sizes on request)

Top styles: snap-band, raw-edge, cord, flange, beaded cuff, J-ring

Bottom styles: disc, welded, reinforced wear-cuff, anti-abrasion cone

Quality: manufactured under ISO 9001 & ISO 14001, 100 % inspected for seam integrity, weight and air-permeability

-

Top Ends

Snap-band | Raw edge | Corded cuff | Beaded cuff | Flange collar | J-ringBottom Ends

Sewn disc | Reinforced disc | Wear-cuff | Welded cone | Venturi integratedCages & Venturis

Epoxy-coated MS, SS 304 or 316; wire Ø 4 – 6 mm; 10–20 ribs; venture lengths matched to bag. -

Air-permeability (ISO 9237)

Mullen burst & tensile (ASTM D3786/D5035)

Thermal ageing & acid-fog exposure per application spec.

Emission validation on in-house pilot rig and third-party stack tests.

-

Process audit – temperature/chemistry profile, air-to-cloth ratio, fan curve.

Media selection & sample trial – lab data + pilot bags in your cell for 90 days.

Full-baghouse rollout – installation supervision or turnkey crew.

Performance verification – leak scan, differential-pressure logging, stack test

Lifecycle monitoring – periodic bag autopsies, optimisation reports, spare-parts planning