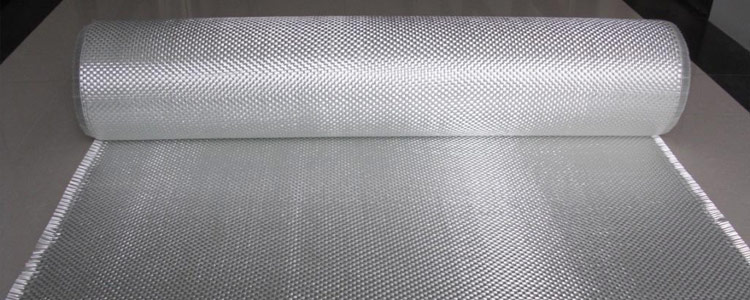

Woven FibreglassFabric

RABH are also used in the cement industry for de-dusting hot kiln gases. Due to very high relative gas temperatures (260 d C to 280 d C) fiberglass is one of the few materials which can be adapted for this application. Of late, pulse jet bag filters also use woven fibreglass fabrics. Yarns of fibreglass are woven into a fabric of between 350gsm to 750 gsm. After weaving, fiberglass fabrics have to be heat cleaned & then coated with different coatings, the most common being the “SILICONE GRAPHITE TEFLON” blend. Other derivatives of this are the “ANT ACID” coating, the 10% PTFE coating etc.

Increasingly, to improve the efficiency of woven fibreglass, they are being thermo laminated with expandable PTFE membranes (e-PTFE). In properly designed bag filters, emissions in sigle digits are not uncommon.